End-to-End Electronic Manufacturing

We take products from design to delivery in the end-to-end electronic manufacturing process.

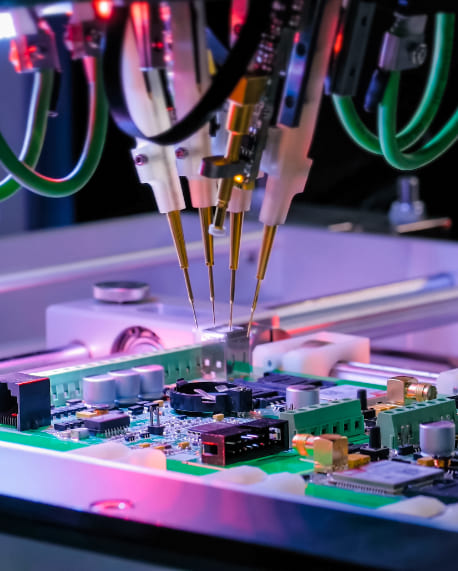

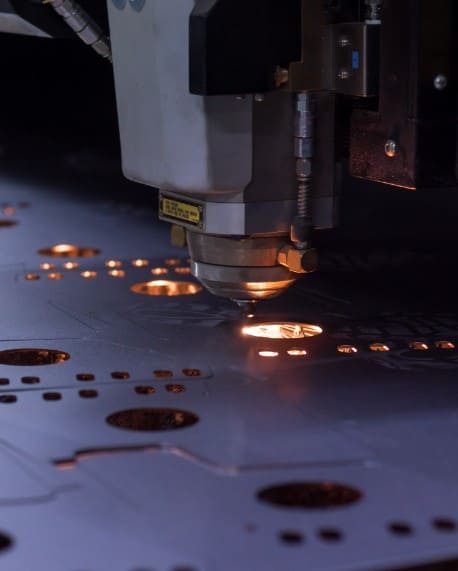

At Vinrox, we offer end-to-end contract manufacturing services that manage the full product lifecycle—from design and engineering to delivery. Our collaborative teamwork, advanced technologies, and custom electronic manufacturing solutions ensure precision, reliability, and quality at every stage. We handle electronics component sourcing, online quality control, and rigorous testing with a customer-first approach. Leveraging innovative electronics design & engineering and technologically advanced equipment, we adapt to evolving needs through our new product introduction (NPI) and value creation practices. Vinrox delivers cost-effective electronics manufacturing with speed, flexibility, and trust—backed by our commitment to quality and continuous improvement.

-

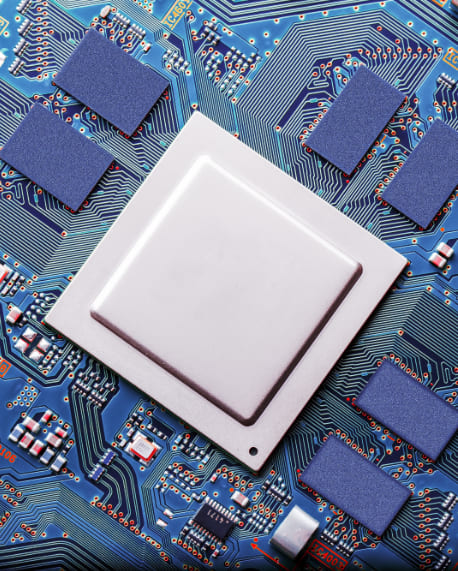

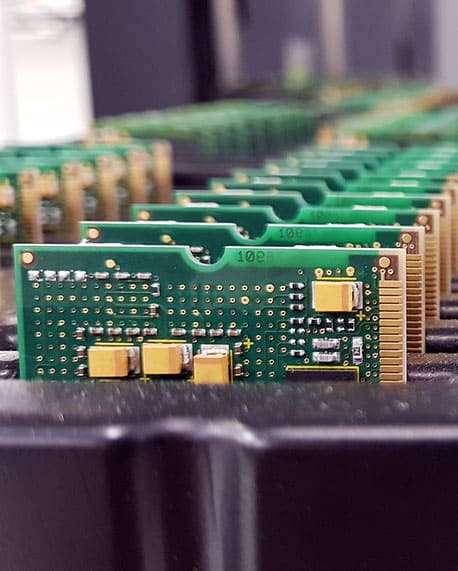

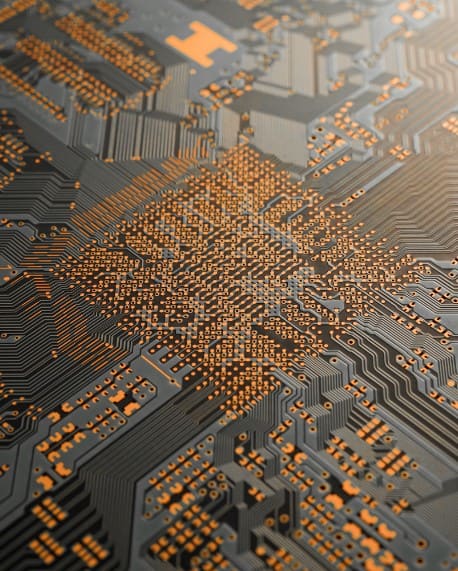

PCB

PCBA

-

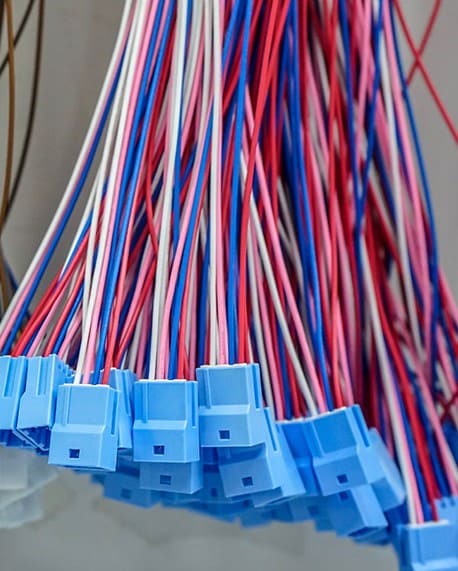

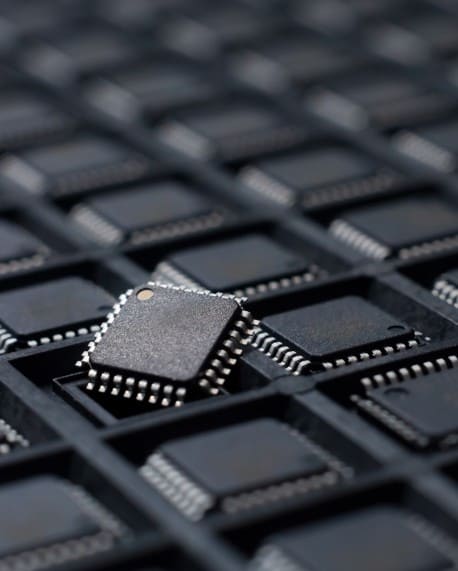

Components

Box Build